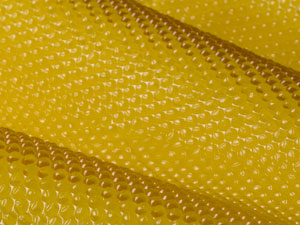

Akton® Viscoelastic Polymer

Akton® viscoelastic polymer has been on the market for over 40 years and is a vulcanized, cross-linked rubber material with unique physical properties. Its ability to maintain its shape, stretch, deflect an applied load and absorb shock makes it an ideal material for many applications. The material is proprietary and produced exclusively in the United States at Action Products, Inc.’s 60,000 square foot facilities in Hagerstown, Maryland.

Akton® viscoelastic polymer has been on the market for over 40 years and is a vulcanized, cross-linked rubber material with unique physical properties. Its ability to maintain its shape, stretch, deflect an applied load and absorb shock makes it an ideal material for many applications. The material is proprietary and produced exclusively in the United States at Action Products, Inc.’s 60,000 square foot facilities in Hagerstown, Maryland.

Through the innovation of the company’s founder, Dr. W.R. McElroy, the Akton® viscoelastic polymer was originally engineered for the treatment and prevention of decubitus ulcers within the medical industry. After widely establishing the use of this remarkable polymer in the medical markets, Action began to explore non-medical markets and today has experienced great success using the material in a variety of new and unique applications.

What Makes Akton® Viscoelastic Polymer So Unique?

- Shock-absorbing

- Supports weight without bottoming out

- X-ray translucent

- High tensile strength and elasticity

- High load-bearing capacity

- Evenly distributes weight

- Hypoallergenic

- Remains pliable from -65F to 285F

- Heat and shear reducing

- Durable bond between surface film and polymer

- Can be molded into any shape or form

- Non-conductive

- Vibration damping

- Won’t leak, flow or bottom out

- Easily repaired if cut

- Fire rated as self-extinguishing

- Ultra-soft to extra-firm durometers

- Latex, silicon and plasticizer free

- Does not support bacterial growth

- Does not harden over time

- Retains it’s original shape after deformation

- Easily cleaned

- Color customized

Our Capabilites

The experience and innovation that the Action Products staff is recognized by allows us to take on projects of all types while consistently meeting the highest standards for a supply partner. From smaller-scale projects to high-volume projects for Fortune 500 customers, we can handle simple to complex design and prototyping and manufacturing of virtually any item, and pride ourselves on our innovative and customer-focused approach to projects. We offer:

- Fully-staffed Engineering and R&D departments

- 3-D CAD modeling

- SLA and CNC machining

- Pressure Mapping Laboratory

- Mold making expertise

- Regulatory Compliance Department with FDA experience

- Lean manufacturing facility

We’re your source for these vibration damping, viscoelastic polymer materials:

Please visit the File Downloads section of this page for additional technical information on the Akton® viscoelastic polymer and our capabilities.

Applications

- Gun recoil pads – Buy Here!

- Equestrian pads – Buy Here!

- Harness pads in Space Ship One

- Tissue equivalent phantom material for radiation therapy

- Trucker seat pad testimonial

- Mattresses designed for cool sleep

- Wheelchair cushions / Operating room pads & positioners

- High performance knee and shoulder padding for stuntmen

- Nano technology

- Vibration damping glove inserts